Aircraft Control Cable Tension Regulator

Aircraft Control Cable Tension Regulator

Control Cable used in an aircraft system such as flight control,engine control and various other mechanism in an airplane to provide input to actuating part of an aircraft system.The use of control cable in flight control system to control elevator,rudder or ailerons and in engine control system to control engine power.

In cable operated device, it is desirable to maintained predetermined cable tension.The tension in cable is subject to variation due to changes in temperature,structural deflection and other environmental influences.

Effect of temperature on cable tension:

The material uses for construction of cable and airframe are different usually stainless steel uses for cable and aluminum alloy for an airframe structure.Thus, the coefficient of expansion and contraction of both metals are different.In aircraft operation temperature changes are drastically, the temperature at sea level may be quite high and at high altitude very low below zero degree.This change in temperature cause expansion and contraction of airframe and cable.

When aircraft flies through high temperature region,its structure expands.Due different coefficient of expansion, the structure expand more than the cable.Thus there will be more tension on cable.

When aircraft flies through cold region, its structure contracts.The contraction of cable lower than that of airframe structure.This result decrease in cable tension.

Effect of structure deflection on cable tension:

When aircraft subject to rapid descent or acceleration of an aircraft in emergency situation cause cable tension to become tight or loose due to rapid airframe structural changes caused by gravitational loading on the aircraft.

It is important that control cable are maintained constantly in tension to prevent loss of control,flutter of control surfaces and correct input for engine control .Control cable tension maintained at ground may not be correct at high altitude due low temperature changes.Thus there is requirement of system which ensure correct control cable tension during an aircraft operation.

Older aircraft were uses the turnbuckle to adjust cable tension.The adjustment of cable tension possible only on ground.Modern aircraft uses automatic cable tension adjuster also called cable tension regulator adjust cable tension automatically throughout all the phases of flights.

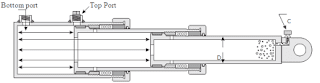

The construction and design of cable tension regulator different for different aircraft but function of all regulator is same.There is scale on tension regulator which indicate correct position of regulator according to temperature compensation.The actual use of regulator scale is for functional check of regulator.With the help of regulator functional check we ensure correct working of regulator. How to do functional check of tension regulator procedure described in aircraft maintenance manual.

In the above picture the alignment of reference mark on regulator support flange and scale on regulator determine temperature compensation position.The scale has thirty divisions: ten for cold temperature compensation ( 0 to R ) and twenty for hot temperature compensation ( 0 to T ).

Please Follow me and Join me on Telegram there you can share your doubt.

https://t.me/joinchat/NxLqTH2cTX9hMjM1

You can also Join me Facebook Group,Link provided below.

https://www.facebook.com/groups/304288677920172/?ref=share

Join us on Instagram link below

https://www.instagram.com/invites/contact/?i=1tv1l3w2dcogj&utm_content=m7ttk5x

Youtube Channel

https://www.youtube.com/channel/UCwfz-cO2H3k8tnA_CMrMKtw

Nice information 👍

ReplyDelete