Aircraft Cabin Differential Pressure Warning

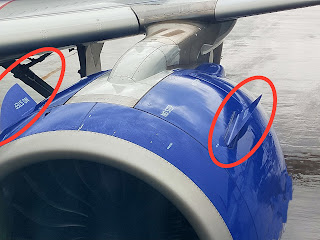

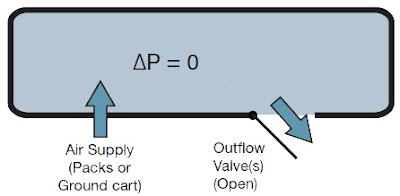

Commercial aircraft usually fly at high altitude to get advantage of fuel economy and calm weather. As the aircraft climb, the atmospheric pressure falls with increase in altitude. The low pressure at high altitude is created the unsafe environment for passengers and crews. Aircraft operating at high cruising altitude is typically equipped with pressurized cabin to protect the aircraft occupant against low atmospheric pressure. Aircraft cabin pressurized with constant pressure is usually maintained 8000 ft cabin altitude. The cabin internal pressure is regulated by automatic cabin pressure control system. Cabin pressure also regulated by flight crew through manual control if automatic cabin pressure control system failed. When cabin pressure is lower than atmospheric pressure negative pressure differential condition developed which is dangerous for aircraft structure. Positive pressure condition is developed when cabin pressure is greater than atmospheric pressure which is hazardo...