Aircraft Structural Components Design Philosophy - Safe-Life & Fail-Safe Design

An aircraft structural components is the main load carrying member. How efficiently structure will take load depends on structural components design and material.Thus , primary consideration in aircraft design is placed on structural components.

There are generally three different types of design philosophies used in designing of structural components which are such as safe-life , fail-safe and damage tolerant design.

Safe-Life Design ;

Original or initial accepted theory of structural components design was safe-life design.According to safe life design concept, the structure designed for finite fatigue life and on reaching this fatigue life structure should be retired from service.A safe life structure components must be remain crack free during their entire time in service.

Safe life structural components service fatigue life is normally consider 25 percent of average life but this consideration of life will not ensure safety of aircraft throughout of its operation because repeated loads of variable magnitude it is extremely difficult to know when catastrophic failure occur.

The safe-life design has some disadvantages.First, it can be uneconomical because components retired from service may not have crack despite having reached stated service life.This problem is aggravate by the fact that the specified service life must be low for the scatter in metal fatigue and uncertainties in service loads.

Second disadvantages, this design approach does not assure safety because, no provision is made for a structure to survive if crack were to exist due undetected material flaw.Once crack started, its propogation life will be very short , leaving no time for routine inspection to detect crack.The structure could prove to be intolerant of relatively small manufacturing defect and , as a result of this ,a crack could quickly grow to failure size well within safe service life of aircraft.

In order to overcome disadvantages of safe -life design, crack propagation based damage tolerance or fail safe design now use for aircraft structure components.

Fail-Safe Design ;

In fail safe design construction each components is designed to accept the force of adjacent components should their neighbouring components fail. A fail safe components design in such a way that after failure of one part of components there will be sufficient strength in reminder part to prevent catastrophic failure until the damaged part is found in routine inspection.Most modern aircraft now using fail safe design for structural components.

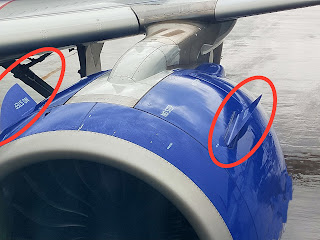

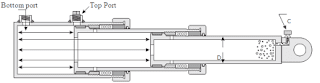

Fail-safe structural fitting design example ;

The structural fitting above in the picture are made into two parts and joined together by riveting.Each half of fitting is capable of carrying full required structural load of assembly.

The big advantage of fail safe design philosophy is failure of one part of components will not result separation of components in flight.This design assure safety of an aircraft.

Please Follow me and Join me on Telegram there you can share your doubt.

https://t.me/joinchat/NxLqTH2cTX9hMjM1

You can also Join me Facebook Group, Link provided below.

https://www.facebook.com/groups/304288677920172/?ref=share

Join us on Instagram link below

https://www.instagram.com/invites/contact/?i=1tv1l3w2dcogj&utm_content=m7ttk5x

YouTube channel link

https://youtube.com/channel/UCwfz-cO2H3k8tnA_CMrMKtw

Comments

Post a Comment